A practical guide to freight modernization for logistics leaders

NOV. 3, 2025

10 Min Read

Your freight network will not keep up on spreadsheets and phone calls alone.

As shipment volumes grow and customer promises tighten, manual coordination starts to strain every team that touches freight. Leaders like you feel the impact as costs rise, service slips, and risk becomes harder to control with confidence. Freight digital transformation gives you a practical path to rebuild operations around data, automation, and more reliable insight.

Executives, data leaders, and technology leaders now face constant pressure to move faster without losing control of cost or risk. Shipping digitalization, modern data platforms, and cloud infrastructure let you redesign freight planning and execution for speed, quality, and scale. Teams need clear guidance on what to prioritize, how to stage investment, and how to connect freight changes to revenue, margin, and resilience. Clear structure around freight and shipping digital transformation will help you link every step to measurable business value.

key-takeaways

- 1. Freight digital transformation provides a path for leaders to replace fragmented manual work with connected, data rich systems that increase control, visibility, and predictability.

- 2. Logistics modernization strengthens cost structure and resilience across modes by improving consistency in data, workflow, and partner coordination.

- 3. Data foundations, visibility platforms, and workflow automation set the stage for AI supported forecasting, exception management, and service improvements.

- 4. Strong alignment across executives, data leaders, and technology leaders is essential to maintain momentum and protect value throughout freight modernization programs.

- 5. Long term freight modernization requires investments in scalable data platforms, integrations, security structures, and configurable transport systems that support measurable business outcomes.

How freight digital transformation reshapes shipping operations today

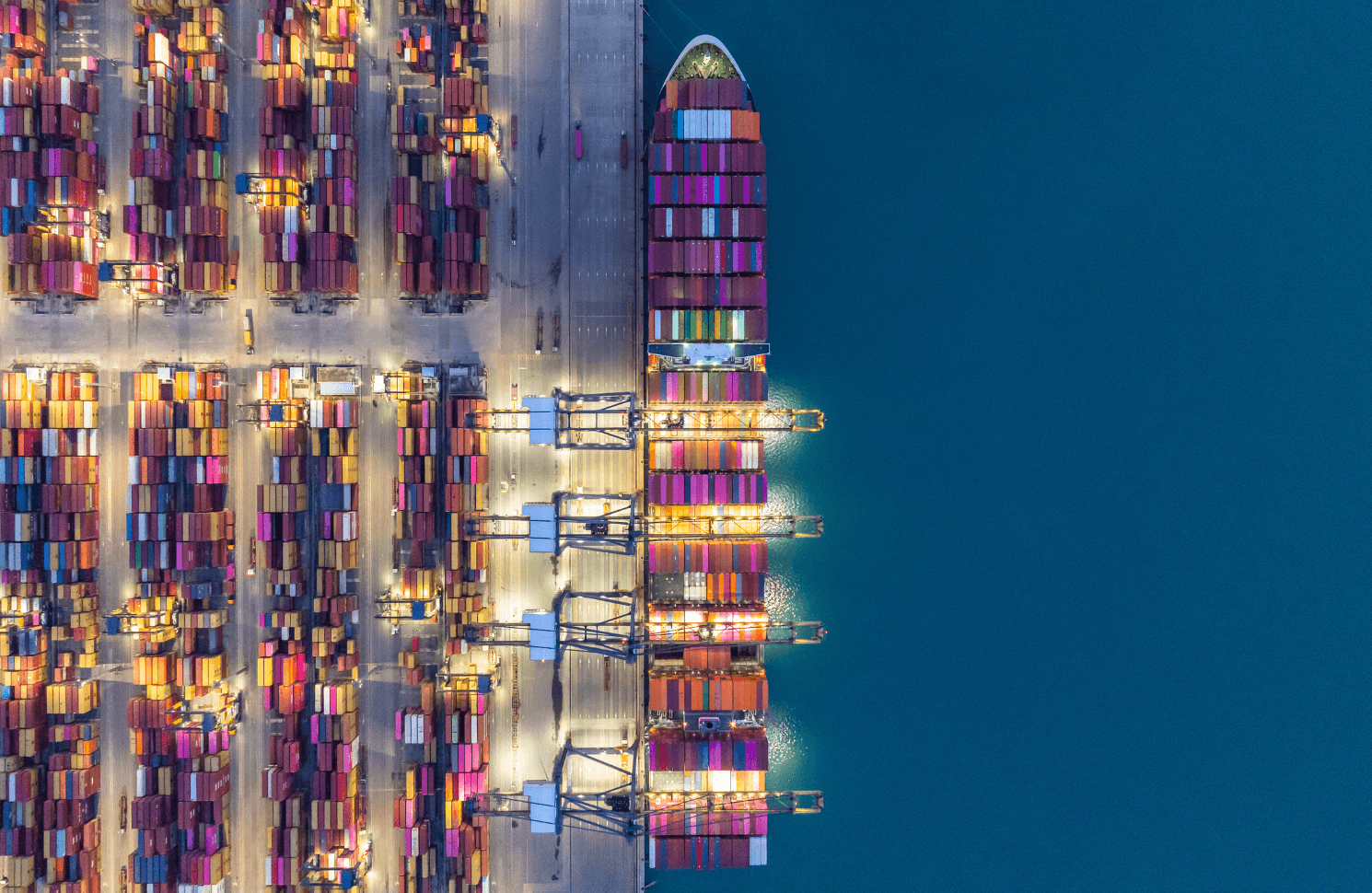

Freight digital transformation refers to a full shift from manual, paper based workflows to connected digital systems across planning, booking, execution, and settlement. Instead of scattered emails and spreadsheets, your teams use transport management systems, data platforms, and automation to coordinate loads, carriers, and routes. Every booking, status update, and proof of delivery becomes structured data that you can query, feed into analytics, and act on in real time. This shift raises the bar on accuracy and traceability, so your operations rely less on heroic manual effort and more on reliable, repeatable processes. For executives, this means freight stops feeling like a black box and starts showing up as a set of manageable levers that link directly to cost, service, and growth.

Shipping digitalization brings that same mindset to the connections between your freight network, customers, and trading partners. Carriers, brokers, and warehouses share data through application programming interfaces (APIs), portals, and integrated platforms instead of ad hoc phone calls. You gain a traceable chain of events for each shipment, from tender to handoff to delivery, with timestamps, status codes, and supporting documents in one place. Operations teams rely on this shared view to make quicker choices on mode, carrier, and routing, which keeps service levels high even when conditions shift. For data and technology leaders, the move to digital channels forms the foundation for more advanced freight tech transformation work such as predictive analytics, digital twins, and AI assistants.

"Shipping digitalization, modern data platforms, and cloud infrastructure let you redesign freight planning and execution for speed, quality, and scale."

Why logistics leaders focus on modernization for cost and resilience

Modernization in freight is not a side project for logistics leaders, it is a direct response to cost pressure, service expectations, and board level scrutiny. Legacy systems and manual workarounds create hidden costs in labor, claims, detention, and missed consolidation chances that never show up clearly in reports. Cargo logistics modernization gives you the structure to systematically address those gaps, rather than fighting fires lane by lane or customer by customer. Clarity on why you invest first in certain flows, regions, or modes will keep your roadmap grounded in the outcomes your leadership team cares about most.

- Lower total freight cost through better consolidation, mode selection, and fewer empty miles, using digital tools that expose patterns you cannot see in spreadsheets.

- Improve service reliability by standardizing processes, timelines, and data handoffs, which reduces exceptions and rework for operations teams and carriers.

- Reduce risk from disruptions, compliance issues, and contract obligations by gaining clearer, real-time visibility into shipments, partners, and obligations with modernization.

- Shorten time to value for new lanes, customers, and services, because digital freight workflows can be copied, tested, and adjusted much faster than manual processes.

- Give finance and executives better line of sight into freight spend, surcharges, and rebates, so they can treat freight as a managed investment instead of a fixed cost.

- Create a foundation for freight tech transformation that supports AI use cases, automation, and more advanced planning techniques without constant rework of your core systems.

When modernization is tied to clear cost and resilience outcomes, it becomes much easier to secure funding and executive sponsorship. Logistics leaders can show how each project links to fewer manual touches, lower error rates, and more consistent customer service. Teams across finance, operations, and technology gain a shared language for tradeoffs between cost, service, and risk across the freight network. That shared clarity sets the stage for digital transformation in logistics that actually sticks instead of stalling after the first wave of pilots.

How digital transformation in logistics improves end to end visibility

Digital transformation in logistics often starts with a simple goal, leaders want to see what is happening across shipments without waiting for manual updates. Visibility is not just a map on a screen, it is a consistent flow of events that connect orders, inventory, freight, and cash. When that flow is digital from the start, you can understand where loads sit, how exceptions build, and which customers or lanes create the most noise. A thoughtful visibility design will protect service levels, free up working capital, and shorten cycle times across your freight network.

Real time shipment tracking across modes and partners

Real time shipment tracking gives you a single view of status across road, ocean, air, and rail. Instead of chasing updates through phone calls and emails, your teams see events like pickup, departure, customs clearance, and delivery inside one system of record. Digital feeds from carriers, telematics devices, and ports create a stream of status messages that logistics teams can trust for daily operations. This view will let planners spot late pickups, missed connections, or dwell time early enough to act before service commitments slip.

For executives, this level of shipment tracking connects freight performance directly to customer experience and revenue protection. Data leaders gain a stable set of events that can feed service level reports, carrier scorecards, and inventory models without constant data wrangling. Technology leaders can design interfaces and event hubs so that shipment data flows into transport systems, customer systems, and analytics platforms without fragile one off integrations. The result is a tracking foundation that supports both day to day operations and more advanced freight digital transformation use cases such as predictive alerts.

Integrated order, inventory, and freight data foundations

True visibility needs more than shipment events, it needs order, inventory, and freight data connected in a shared model. When logistics teams see orders in isolation, they struggle to understand which delays actually matter to customer promises and revenue. When inventory is spread across separate systems, planners cannot balance stock levels with transit times and service targets consistently. Integrating data across these domains lets you ask better questions about cost to serve, lead times, and customer impact.

Data leaders will care about how this model is structured, including the design of master data, reference tables, and quality checks. Technology leaders will focus on how data moves between enterprise resource planning systems, transport systems, and data platforms in real time. Executives will look for a clear connection between this integrated model and tangible outcomes such as lower working capital and fewer missed orders. Digital transformation in logistics gains staying power when all three groups see that shared data foundations support their goals without constant rework.

Exception management for earlier intervention on risk

Exception management uses all that visibility data to surface the shipments and orders that need attention before service fails. Instead of scanning long lists of loads, your teams work from queues of at risk shipments filtered by lane, customer, or service level. Rules, alerts, and AI models highlight combinations of events, such as repeated handoffs or long dwell time, that signal a higher chance of delay. Operations staff can then contact partners, adjust routing, or reset customer expectations while there is still time to act.

For executives, this approach reduces surprise escalations from key customers and protects revenue that might otherwise slip out of quarter. Data leaders will treat exception data as a rich source for route design, carrier selection, and process improvement. Technology leaders can design event rules, workflow engines, and case management tools that fit existing roles instead of forcing a new structure overnight. Exception management becomes one of the most visible signs that freight tech transformation is working, since leaders see fewer last minute crises and more controlled responses.

Customer facing visibility that reduces manual status requests

Customer facing visibility turns internal shipment tracking into a consistent experience for buyers, receivers, and internal sales teams. Portals, notifications, and status feeds give each stakeholder the right level of detail without flooding them with raw system events. Shippers can share estimated arrival times, exception codes, and proof of delivery in a format that customers understand and trust. This approach reduces inbound calls, emails, and escalations, which frees your teams to focus on more valuable work.

Sales and account teams gain confidence when they can see the same information as logistics teams instead of relying on second hand updates. Customer service staff can focus on higher value conversations about options and preferences, since basic status questions are already answered digitally. Executives see customer visibility as an extension of the brand, because freight performance now supports what marketing and sales promise. Customer facing visibility also builds trust that supports more collaborative planning around inventory, replenishment, and promotions.

| Visibility focus | Digital capability | Operational impact |

|---|---|---|

| Shipment progress | Carrier and device status feeds | Earlier awareness of delays and dwell time |

| Order to delivery linkage | Integrated order, inventory, and freight data model | Clear view of which orders are at risk in transit |

| Exception handling | Rules engines and AI based risk scoring | Fewer surprises and more controlled responses |

| Customer experience | Portals and proactive notifications | Lower inquiry volume and higher satisfaction |

| Performance analysis | Historical event store and analytics tools | Better route, carrier, and network design choices |

Strong visibility starts with reliable data capture, but real value emerges when that data shapes daily freight decisions. When shipment tracking, integrated data models, exception flows, and customer views work in sync, logistics teams achieve a calmer, more predictable operation. Executives, data leaders, and technology leaders can all point to the same set of visibility metrics when discussing service, cost, and risk. That shared view prepares your organization for deeper freight digital transformation steps such as automated planning, dynamic pricing, and more advanced AI support.

Core freight tech transformation priorities for modern supply chains

Once visibility foundations are in place, freight tech transformation becomes a question of where you focus first for impact. Leaders who pick clear, contained priority areas will show value faster and avoid overwhelming operations teams. The right focus areas will connect infrastructure choices, such as data platforms and integration layers, with practical improvements in planning, execution, and billing. You will also create a structure for sequencing projects so that each step supports the next rather than adding one off point solutions.

- Modern transportation management system design that treats TMS as the orchestration hub for planning, rating, tendering, and settlement across modes.

- Unified freight data platform that stores shipment, order, and cost data in a consistent model ready for analytics, AI, and financial reporting.

- Integration and API strategy that connects carriers, brokers, warehouses, and internal systems with reusable patterns instead of one time custom links.

- Automation of routine tasks such as tendering, appointment scheduling, and documentation, which frees planners to focus on exceptions and network design.

- AI assistants for planners and customer teams that summarize status, suggest actions, and highlight trends without replacing human judgment.

- Security, access control, and audit capabilities that protect freight data, support compliance needs, and build trust with partners and regulators.

Each of these priority areas will touch more than one team, so alignment on owners, funding, and timeframes matters as much as the technology itself. Executives should link each freight tech investment to clear measures such as on time performance, cost per shipment, or working capital improvements. Data and technology leaders can use these priorities to guide platform choices, talent planning, and vendor selection over the next several years. When everyone understands how these freight tech transformation priorities support growth, margin, and resilience, it becomes much easier to maintain momentum.

How data and AI tools improve forecasting and shipment accuracy

Forecasting and shipment accuracy sit at the center of freight performance because they shape how much you spend and how well you keep customer promises. Data and AI tools will help you see patterns that humans miss, smooth out noise in volume, and adjust plans as conditions shift. Digital freight data provides the raw material for these tools, from shipment histories and order patterns to carrier performance and dwell time. When you use that data thoughtfully, you can reduce surprises, protect margin, and give operations teams a calmer plan to execute each day.

Using historical freight data to improve volume forecasts

Historical freight data holds a detailed record of lanes, modes, customers, and seasonality that planners often reference informally. AI models can scan this data at scale, spotting correlations and patterns that point toward more accurate volume expectations by lane and week. You can feed in order histories, booking lead times, and external signals such as promotions or product launches to sharpen those forecasts further. Better volume forecasts help you secure capacity, set service expectations, and plan network changes with more confidence.

Executives care about how improved forecasts affect revenue plans, capital allocation, and customer commitments. Data leaders will focus on the quality of input data, how forecasting models are validated, and how often they are refreshed. Technology leaders must ensure that data flows from operational systems into forecasting tools in real time and back into planning systems without manual file uploads. When these roles align around shared forecast outputs, freight teams can act on a single plan rather than debate whose numbers to trust.

Applying machine learning models to shipment risk scoring

Shipment risk scoring uses machine learning to estimate which loads are more likely to arrive late, incur extra cost, or trigger service issues. Models consider factors such as lane history, carrier performance, load characteristics, and timing, and then assign a risk score before execution. Planners can use these scores to adjust mode, carrier, or routing, or to add buffers for sensitive customers. Operational teams focus first on high risk loads, which leads to fewer surprises even when conditions are difficult.

Executives appreciate that risk scores provide an early warning system that ties directly to revenue protection and customer satisfaction. Data leaders will define governance for these models, including how data is sourced, monitored for bias, and retrained. Technology leaders will integrate risk scores into existing workbenches, mobile tools, or control towers so planners can act without switching systems. Over time, shipment risk scoring becomes part of the daily rhythm of planning, which keeps freight digital transformation grounded in practical use cases.

Aligning pricing and margin analysis with freight performance

Freight costs often sit in separate systems from pricing and margin analysis, which makes it hard to see true profitability by customer or product. Linking freight data with pricing and revenue data helps you understand where underpriced lanes or service promises erode margin. AI tools can cluster customers and lanes with similar cost and service profiles, which supports more consistent pricing and contract terms. Sales and logistics teams then have a shared view of what it takes to deliver each commitment and which service mix actually supports profit targets.

Executives will see this alignment as a direct lever for earnings, since freight spend is a major line item that will now tie cleanly to revenue. Data leaders can standardize cost to serve models, keep assumptions transparent, and run simulations to test new pricing structures before rollout. Technology leaders support this work with data platforms that link freight events, cost allocations, and pricing data at the transaction level. When freight performance and margin analysis live in the same frame, commercial and logistics teams stop working at cross purposes and start solving the same problem.

Feeding operational insights back into planning cycles

Operational teams see daily details that may not always appear in dashboards, such as recurring documentation issues or locations that consistently load slowly. Digital tools can capture these insights as structured feedback, which then feeds into models, route guides, and policy updates. When planners and data teams review that feedback on a set cadence, they can adjust forecasts, routing guides, and carrier allocation with better context. This loop keeps freight planning connected to reality on the ground so models stay useful instead of drifting away from how work actually happens.

Executives can sponsor this feedback loop by asking for regular summaries of key freight learnings and how they impact cost, service, and risk. Data leaders will work on how to collect, classify, and prioritize this feedback so it improves models instead of creating noise. Technology leaders will provide the collaboration tools, workflow engines, and data structures that keep insights tied to specific shipments or lanes. Over time, this continuous improvement loop turns freight digital transformation from a one time project into a sustained way of working that keeps performance improving.

Data and AI do not replace the experience of your freight teams, they multiply the value of that experience with better forecasts and earlier signals. When you line up historical data, risk models, pricing insight, and feedback loops, your shipment plans become more reliable and less stressful to execute. Executives, data leaders, and technology leaders can all see how these tools protect revenue, margin, and service without adding unnecessary complexity. That confidence creates the conditions for more ambitious freight tech transformation projects that still stay rooted in day to day realities.

Technology investments that support long-term freight modernization goals

Freight modernization succeeds only when the technology you choose can carry your business for several planning cycles, not just one project. Short term fixes might solve a single integration or a single reporting request, but they add fragility as your network grows. An intentional investment view keeps you focused on platforms, patterns, and skills that will support many freight initiatives over time. This approach also gives executives and finance leaders a clearer story about payback periods, depreciation, and total cost of ownership.

- Cloud based data platforms that consolidate freight, order, and financial data with strong governance, quality checks, and scalable storage and compute.

- Modern integration layers that support APIs, streaming events, and file based flows so carriers and partners can connect in a structured, reusable way.

- Configurable transportation management and warehouse management systems that can adjust to new modes, markets, and operating models without heavy custom code.

- Analytics and visualization tools that let business users slice freight performance by lane, carrier, product, and customer without long waits for custom reports.

- AI and automation capabilities, such as workflow engines and copilots, that plug into your data platform instead of existing as isolated point tools.

- Security, identity, and access management frameworks that protect data, support audits, and maintain trust with regulators and partners.

A clear technology investment map keeps your freight roadmap aligned with architecture choices, so each new use case reuses the same core capabilities. Executives will appreciate that this approach spreads spend across multiple initiatives, improving payback and reducing surprise budget spikes. Data and technology leaders gain space to design for reliability, observability, and maintainability instead of rushing from one urgent integration to the next. Over time, this steady foundation supports more ambitious cargo logistics modernization goals, from new service models to more advanced AI supported planning.

How leadership teams align around freight digital transformation success

Freight digital transformation only delivers full value when executives, data leaders, and technology leaders pull in the same direction. Misalignment shows up as stalled projects, finger pointing, and fatigue on the warehouse floor or in control rooms. Clear roles, shared goals, and transparent communication will turn digital freight work into an integrated part of your strategy instead of a parallel effort. Alignment requires intentional work on value cases, governance, and change support, not just technology selection.

Building a shared value case across finance and operations

A shared value case explains how freight digital transformation affects revenue, cost, risk, and working capital in terms every leader understands. Finance teams want to see how initiatives affect earnings and cash flow, while operations want clarity on workload, service levels, and staffing. A structured value case will tie each initiative to a small set of metrics, such as on time in full performance, cost per shipment, and order to cash cycle time. When all parties agree on these measures before projects start, debates about success become much simpler.

Executives should sponsor this value work personally, since it connects freight decisions to board level goals and investor expectations. Data leaders can help quantify impacts, design baselines, and set up dashboards that track those metrics consistently. Technology leaders will weigh in on feasibility, sequencing, and integration complexity so that the value case reflects realistic delivery paths. A well understood value case makes it easier to secure approvals, align incentives, and adjust scope without losing sight of outcomes.

Clarifying ownership for data, platforms, and outcomes

Freight programs often stall when no one is sure who owns data quality, process changes, or platform upgrades. Clear ownership structures assign responsibility for data domains, application portfolios, and process design to specific leaders or teams. This structure helps avoid gaps where issues bounce between groups, such as disputes over carrier master data or unclear rules for access to freight cost details. RACI charts, steering groups, and operating forums can support this clarity without adding unnecessary bureaucracy.

Executives can define which committees and roles hold final authority for tradeoffs that span functions, such as balancing service levels against cost. Data leaders will define stewardship roles, escalation paths, and expectations for data quality reviews. Technology leaders will take clear responsibility for uptime, performance, and incident response for key freight systems and integrations. When ownership is explicit, teams know where to go for answers, and projects move forward more smoothly.

Addressing security, privacy, and compliance expectations

Freight digital transformation introduces new data flows, integrations, and tools that must align with security and privacy standards. Customer data, shipment details, and partner information all need clear handling rules, access controls, and retention policies. Security teams will ask for evidence that freight systems comply with frameworks such as ISO or SOC, and that access is logged and reviewed. Addressing these needs early avoids last minute delays during audits, customer reviews, or partner onboarding.

Executives should view strong security and compliance practices as a way to protect brand reputation and maintain trust with customers and regulators. Data leaders can work with security teams to classify data, define usage policies, and design anonymization or tokenization where needed. Technology leaders must architect freight platforms with encryption, identity management, and monitoring built in from the start. When security is embedded in freight modernization plans, leaders spend less time reacting to issues and more time focusing on growth and service outcomes.

Investing in change support and frontline adoption

Freight digital transformation often changes how planners, dispatchers, and warehouse staff do their daily work. If those teams feel left out of design and rollout, they will create their own workarounds, which undermines data quality and process consistency. Structured change support includes early involvement, clear role definitions, training, and feedback channels that keep frontline voices present. Super users and champions in each location can help peers gain confidence with new tools and workflows.

Executives send a strong signal when they show up in kickoff sessions, town halls, or floor visits to discuss why freight changes matter. Data leaders can build simple, trustworthy reports that show frontline teams how their use of systems affects service, cost, and error rates. Technology leaders should prioritize usability, response time, and reliability so new tools feel like a help rather than a burden. When frontline adoption is treated as a core workstream, freight digital transformation becomes something people are part of instead of something that happens to them.

Alignment across leadership, governance, security, and change support keeps freight initiatives from stalling after early wins. Executives maintain a clear link between freight digital transformation and the growth, margin, and risk objectives they share with the board. Data and technology leaders work from a stable structure for priorities, ownership, and success measures, which reduces friction in daily collaboration. With this alignment in place, your organization is ready to extract real business value from freight and shipping digitalization at scale.

"A structured value case will tie each initiative to a small set of metrics, such as on time in full performance, cost per shipment, and order to cash cycle time."

How Lumenalta supports freight and shipping digital transformation goals

Lumenalta works with leadership teams that need freight to support growth, not just keep goods moving from point A to point B. We focus on connecting AI, data, and cloud investments to specific freight outcomes such as better visibility, lower cost per shipment, and more reliable service. Our teams partner with you to design freight data foundations, select or refine transport and warehouse systems, and build integration patterns that match your current and future needs. You gain a clear view of how each freight initiative ties to value, from the first discovery sessions through pilots and scaled rollout.

For executives, Lumenalta provides decision support, value cases, and governance structures that stand up to board level questions about payback and risk. For data leaders, we bring reference models, quality frameworks, and AI use case design that fit freight realities instead of generic templates. For technology leaders, we offer architecture guidance across data platforms, security, and integration layers so freight workloads remain stable, observable, and ready for growth. These strengths give Lumenalta a trusted role as a long term ally for freight digital transformation, and you can rely on that partnership as stakes and expectations increase. When you work with Lumenalta, you work with a team that treats your freight goals as board level priorities and backs every recommendation with accountable delivery.

table-of-contents

- How freight digital transformation reshapes shipping operations today

- Why logistics leaders focus on modernization for cost and resilience

- How digital transformation in logistics improves end to end visibility

- Core freight tech transformation priorities for modern supply chains

- How data and AI tools improve forecasting and shipment accuracy

- Technology investments that support long term freight modernization goals

- How leadership teams align around freight digital transformation success

- How Lumenalta supports freight and shipping digital transformation goals

Want to learn how digital transformation can bring more transparency and trust to your operations?