9 reasons CIOs are using AI for warehouse and fleet optimization

JUL. 30, 2025

6 Min Read

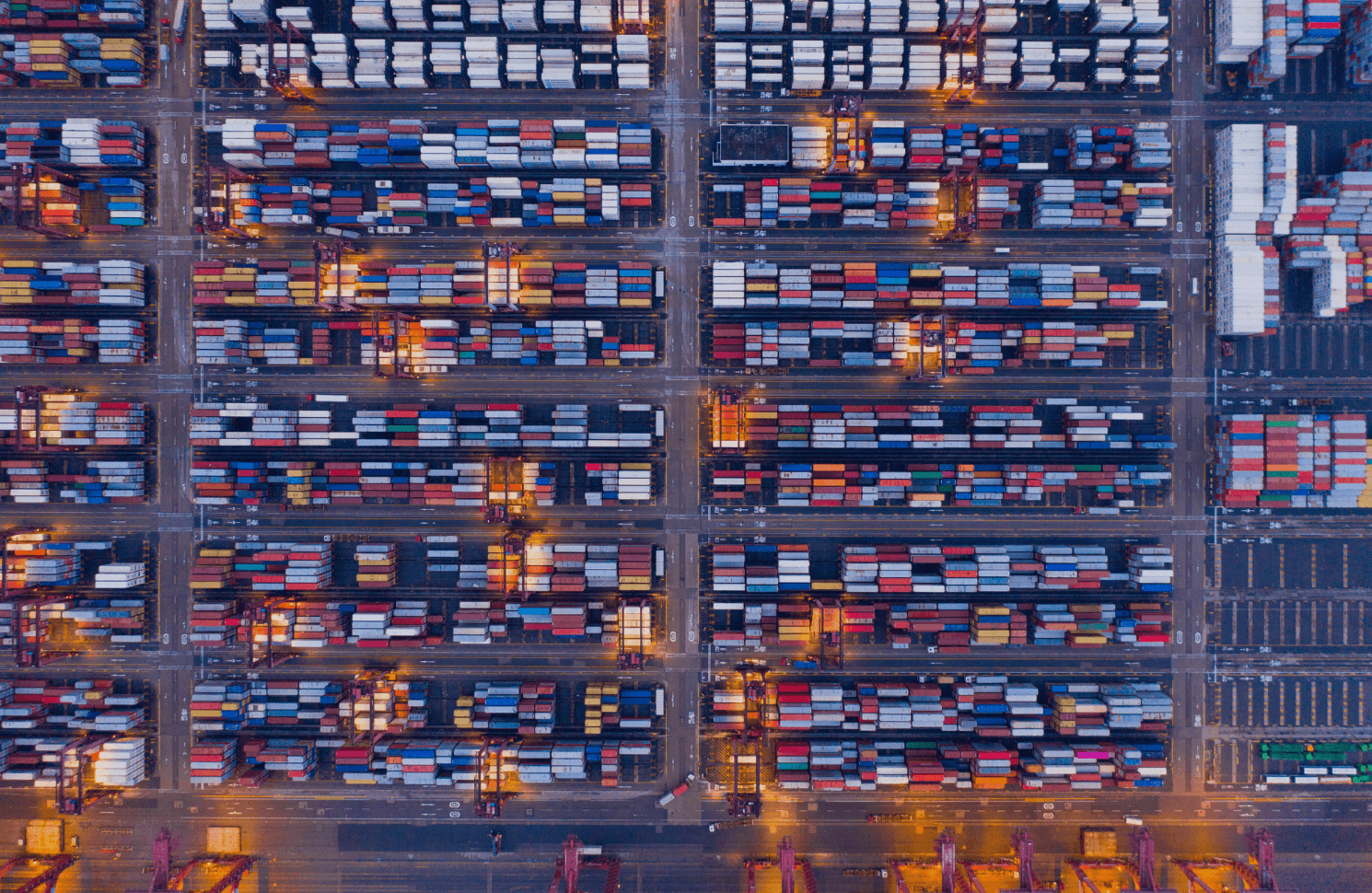

AI now delivers precise operational visibility for every warehouse aisle and delivery route.

Technology leaders no longer wait days for status reports because predictive algorithms surface issues the moment they occur. Greater transparency translates into lower costs, happier customers, and stronger confidence at board meetings. The shift is practical, measurable, and squarely within reach for CIOs who manage logistics networks.

Cloud platforms, computer vision, and machine learning work in concert to connect forklifts, pallets, and trucks to a single data fabric. This unified view collapses silos between warehouse management systems and fleet telematics so you act on a shared source of truth. When your fulfillment center sends inventory forecasts to the dispatch console, arrival times become promises instead of estimates. Stakeholders appreciate that every operational decision is backed by hard numbers rather than hunches.

Key takeaways

- 1. AI enhances operational visibility by integrating warehouse and fleet data into a real-time decision support system.

- 2. Predictive algorithms improve route planning, inventory forecasting, and equipment maintenance for measurable cost savings.

- 3. Labour planning and task allocation become smarter and more efficient, increasing productivity without adding headcount.

- 4. AI reduces downtime, improves service reliability, and accelerates order fulfilment to meet high customer expectations.

- 5. Scalable AI execution depends on data quality, integration readiness, and clear ROI frameworks to ensure business alignment.

How AI improves operational visibility across fleet and warehouse

Computer vision cameras count pallets, while telematics devices stream speed and location data from each tractor‑trailer. Machine learning unifies these signals into time‑coded events that reveal exactly where assets sit, move, or queue. This approach to AI in fleet management cuts the guesswork that typically leads to over‑ordering fuel or misallocating drivers. At the same time, supervisors spot congestion on loading docks before schedules slip.

For AI for warehouse management, predictive algorithms examine historical pick rates, seasonal bookings, and supplier lead times. The system adjusts reorder points and slotting rules hours before human planners would even notice a trend. When combined with dynamic vehicle routing, the result is a closed feedback loop between storage and delivery. You enjoy a live view of every order’s journey, from shelf location to proof of delivery, without manual reconciliation.

See vision AI in action

"You enjoy a live view of every order’s journey, from shelf location to proof of delivery, without manual reconciliation."

9 benefits of using AI in warehouse and fleet management

Operational visibility is only the beginning because advanced analytics directly tackles bottlenecks that erode profit margins. Predictive models cut waste, optimize human resources, and safeguard equipment before faults disrupt schedules. The financial impact shows up as fewer miles driven, tighter inventory turns, and faster cash cycles. Logistics teams experience measurable gains once connected data flows into algorithmic decision support.

1. Improved route efficiency using AI in fleet operations

Dynamic routing engines ingest traffic, weather alerts, and loading dock availability in real time to calculate the shortest feasible path. The algorithm reroutes a driver the moment congestion threatens on‑time arrival, saving fuel and overtime hours. Dispatchers no longer rely on gut feel because every detour is justified by live data from the field. Large carriers report mileage reductions of up to eight percent after shifting route planning to machine-learning models.

Route optimization also balances delivery windows against driver hours‑of‑service compliance so your operation stays well within safety regulations. When stops are sequenced according to dwell times and unloading constraints, dwell fees shrink and loaders spend less time idle. Customers benefit through narrower ETA windows that rarely slip, which boosts satisfaction scores without adding vehicles to the fleet. Better route efficiency frees capital that you redirect toward growth projects or next‑generation equipment.

2. Increased accuracy from AI for warehouse inventory forecasting

Machine learning studies multi‑year order histories, current promotions, and macroeconomic signals to predict order volume with granularity down to the SKU and day. The forecast engine recalibrates every hour as new sales appear, keeping inventory positions aligned with true market consumption. Planners avoid tying up capital in slow‑moving items and sidestep costly stockouts on popular lines. Higher forecast precision leads to tighter coordination with fleet schedules because pallets are ready the moment trucks back into bays.

Implanting these models inside existing warehouse management software takes minimal change to daily workflows because suggested reorder points surface as familiar fields. Your team reviews the recommendation, accepts it with one click, and moves on to higher‑value analysis. Cost savings show up not only in inventory carrying expenses but also in reduced last‑minute freight surcharges. Suppliers appreciate steadier purchase orders, and your finance department sees healthier cash‑to‑cash cycles.

3. Reduced operational downtime with AI in fleet management

Downtime often hides in small gaps between loading, driving, and maintenance events that slip through manual oversight. AI-based monitoring tools highlight patterns of idle time across driver shifts, layovers, and yard waits. Supervisors then adjust dispatch sequences or call for cross‑docking to keep trailers rolling. Even a five‑minute cut per stop aggregates into hundreds of productive hours each month.

Telemetry integrated with warehouse dock management prevents trucks from queuing because bays are allocated only when inventory is staged and paperwork is cleared. This coordination lowers fuel burn associated with engine idling and reduces demurrage charges at customer sites. You reclaim capacity that once sat unnoticed, which postpones costly fleet expansion. Downtime metrics feed future scheduling simulations so improvements keep compounding over time.

4. Real-time decision support through AI in warehouse systems

Vision analytics monitor pick faces and flag empty slots to replenishment teams before fast movers run dry. Robust recommendation engines adjust pick paths on the fly so workers cover fewer steps per order. Supervisors watch digital twins that replay forklift routes, revealing unexpected congestion points. Because insights arrive in real time, corrective action occurs within the same shift rather than at next‑day reviews.

The same framework triggers automated task interleaving, assigning workers to value‑adding moves whenever their primary responsibility stalls. This keeps labor utilization consistently high without overloading staff. Alerts appear within familiar handheld devices, avoiding disruptive context switches. Clear, timely guidance raises throughput while maintaining safety compliance.

5. Enhanced labor allocation using AI for warehouse optimization

Labor planning historically relies on weekly averages that mask hourly surges. AI‑powered forecasting breaks the day into fifteen‑minute increments and predicts order intake by channel. Supervisors schedule part‑time or cross‑trained staff precisely where and when volume peaks. This approach reduces overtime payouts and improves worker satisfaction because shifts end on time.

Computer vision also validates pick accuracy, freeing experienced employees to handle exceptions and coaching rather than constant inspection. The system assigns complex tasks to skilled workers and simpler picks to new hires, accelerating onboarding. Attrition drops when staff feel their skills are used wisely and metrics reflect real performance. Management gains a reputation for fairness based on data rather than perception.

6. Predictive maintenance through AI in fleet operations

Engines, brakes, and refrigeration units stream vibration, temperature, and fluid data to cloud databases every few seconds. Models compare current readings to historical failure signatures and send maintenance tickets long before fault codes surface on the dashboard. Technicians schedule repairs during low-utilization windows instead of roadside emergencies. This foresight slashes tow costs and protects on‑time delivery statistics.

Spare parts ordering becomes more precise because lead times align with predicted service dates. Warehouse staff know exactly when a tractor will return for service, so they reserve docking space and avoid surprises. Insurance providers often reward fleets that prove predictive maintenance programs with lower premiums. Lower risk and higher asset availability release budget capacity for strategic initiatives.

7. Faster order fulfillment powered by AI in warehouse management

Wave planning engines group orders with similar routes or product profiles, shortening travel distance for pickers. Robots and conveyors then coordinate with human teams through orchestration software that balances load across zones. Customers see same‑day or next‑day delivery options without sacrificing margin. Order accuracy also improves because the system double‑checks SKU scans against allocation rules.

Cycle times drop further when AI sequences packing and labeling lines in step with carrier pickup schedules. Packages leave the dock at optimal truck fill rates, keeping freight rates low. Improved fulfillment speed tightens the feedback loop between sales promotions and inventory turnover. You convert revenue faster while sustaining operational discipline.

8. Cost reduction through AI-driven warehouse and fleet insights

Every sensor reading feeds a cost‑to‑serve model that allocates expenses down to the individual order. Analytics highlight high‑cost customers or routes that erode margin, giving you hard evidence for renegotiation or process adjustment. Fuel optimization, right‑sized inventory, and lower labor overtime combine into a measurable reduction in cost per unit shipped. Finance teams use these numbers to forecast savings scenarios and justify further AI investments.

AI‑based insights also spot under-utilized trailers, pallets, and storage locations, so you can retire or repurpose assets before they depreciate. Avoiding unproductive capacity directly improves return on invested capital metrics that boards scrutinize. Savings extend to sustainability initiatives because fewer empty miles mean lower emissions fees. Cost reduction thus strengthens both financial and corporate responsibility goals.

9. Higher service levels with AI in fleet and warehouse coordination

Tight coupling between warehouse availability and fleet ETAs improves on‑time in‑full metrics that shippers track closely. AI alerts customer service teams of potential delays while there is still time to adjust routes or shift stock between depots. Clients appreciate proactive updates rather than apologies, leading to higher renewal rates. Improved predictability also reduces dock congestion at customer sites, reinforcing trust.

When service levels climb, sales teams confidently pursue new contracts without fearing operational strain. Positive performance data serves as proof points during quarterly business reviews. Carriers and facility managers collaborate using the same data views, cutting email chains and mismatched spreadsheets. The organization builds a reputation for reliability that supports premium pricing.

Artificial intelligence delivers compound efficiencies because each improvement amplifies gains from the preceding one. Better routing reduces fuel spend, which lowers the total cost to fulfill inventory that was already optimized by precise forecasting. The net effect is a self‑reinforcing system that keeps operations lean even as order volume grows. CIOs appreciate that these advantages are quantifiable and directly linked to decisions validated by data, not intuition.

Key considerations for scaling AI in warehouse and fleet systems

Initial pilots often look impressive, but wider deployment introduces hurdles that deserve attention early. Careful planning prevents technical debt and preserves the credibility of your analytics program. Scaling success rests on both technology alignment and organizational readiness. Address these focal points before funding a large roll‑out to secure fast payback.

- Data quality and governance: Reliable algorithms start with accurate, time‑stamped data merged under consistent definitions. Invest in automated validation routines so inaccurate sensor feeds do not pollute forecasts or routing plans.

- System integration architecture: Open APIs and message queues allow warehouse management, transportation management, and ERP software to share events within seconds. This connectivity removes manual re‑keying that would otherwise slow decision support.

- Change management and upskilling: Operators must trust recommendations, so training sessions should tie model outputs to familiar key performance indicators. When teams see quick wins, adoption accelerates and shadow processes fade.

- Scalable cloud infrastructure: Elastic computing accommodates seasonal spikes without forcing you to overprovision hardware. Pay‑as‑you‑use billing aligns cost with value creation and keeps the total cost of ownership predictable.

- Cybersecurity and privacy controls: Connected assets expand the attack surface, so encryption, zero‑trust networking, and strict role‑based access remain non‑negotiable. Transparent policies reassure customers that their shipment data stays secure.

- ROI tracking framework: Define baseline metrics before deployment and publish dashboards that update automatically. Continuous measurement safeguards the budget and highlights new optimization opportunities.

Attention to these considerations shortens the distance between proof of concept and full production. When you govern data, architecture, and skills with equal care, scaling feels like a predictable project rather than a gamble. Security and ROI tracking maintain executive sponsorship because results stay visible and risks stay contained. A disciplined rollout, therefore, converts early enthusiasm into sustained operational excellence.

See vision AI in action

"Every sensor reading feeds a cost‑to‑serve model that allocates expenses down to the individual order."

How Lumenalta supports AI‑driven visibility across logistics operations

Lumenalta unifies telematics feeds, warehouse events, and supplier data in a single cloud workspace built for executive speed. Our engineers configure connectors to your existing transportation and warehouse systems within weeks, not months, so you start seeing route, labor, and capacity insights almost immediately. Predictive models arrive pre‑tuned with industry templates, yet remain fully adjustable to your specific service‑level agreements and cost structures. Because dashboards map directly to cost‑per‑mile, cost‑per‑pick, and carbon metrics, finance and operations teams share a common language when allocating budget. You gain the practical agility required to keep customer promises without ballooning capital expenses.

Continuous improvement is built into the platform through automated model retraining and fortnightly feature releases delivered under our "ship weekly" engagement style. CIOs appreciate that governance is embedded, with audit trails and role‑based access baked into every workflow from the outset. Our co‑creation approach pairs your domain experts with our data scientists so adjustments happen in hours, preserving momentum when market conditions shift. Each enhancement is tested against live KPIs before release, which means value creation remains transparent and defensible. Trusted results, predictable delivery cadences, and measurable impact define the Lumenalta partnership.

Common questions

How can AI improve my logistics operations beyond just automation?

What are the top business benefits of AI in fleet operations?

Where does AI provide the most impact in warehouse management?

How do I know my AI investments will generate measurable ROI?

What’s the best way to start AI implementation in my logistics tech stack?

Transform every route and aisle into a data-backed advantage.