Why modern warehouses are breaking up with Excel

Mid-market warehouses relying on Excel spreadsheets are hitting a wall.

Spreadsheets create delays, disconnects, and blind spots that undermine operational agility. Teams often spend hours reconciling mismatched CSVs and static reports emailed across departments. Every data handoff is an opportunity for error: in fact, research shows 90% of spreadsheets with over 150 rows contain one or more faults, meaning critical numbers are likely flawed. As stock moves constantly, these static snapshots soon fall out of sync with reality, delaying shipments and creating miscounts.

"Mid-market warehouses relying on Excel spreadsheets are hitting a wall — spreadsheets create delays, disconnects, and blind spots that undermine operational agility."

Key takeaways

- 1. Excel introduces lag, manual work, and blind spots that delay fulfillment and degrade operational insight.

- 2. Warehouse teams struggle with static data, version conflicts, and disconnected systems that limit agility.

- 3. Modern warehouses don’t need expensive WMS replacements—they need a smarter way to connect the tools they already rely on.

- 4. A real-time data fabric improves coordination, speeds up every process, and helps teams make confident decisions without extra overhead.

- 5. Lumenalta replaces spreadsheet chaos with real-time visibility and faster insight-to-action, without disrupting your current stack.

Meanwhile, IT teams stay busy patching together fragile reporting pipelines just to keep data flowing, and business leaders struggle to trust the numbers. Without reliable real-time insights, even simple decisions drag on. This is reflected at the top: 89% of CFOs say they end up making decisions based on incomplete or inaccurate data, undermining confidence and speed in every step of the supply chain.

Connect your warehouse tools for real-time insight and faster fulfillment. Say goodbye to manual data wrangling and move forward with confidence.

Why Excel is holding modern warehouses back from real-time fulfillment

Manual reconciliation delays orders

Warehouse staff often spend hours reconciling inventory counts across multiple spreadsheets and emailed reports, slowing every transaction. When one report shows stock available and another shows it reserved, someone must find and fix the discrepancy before fulfillment can proceed. This manual back-and-forth means orders often sit in limbo while teams double-check figures. These delays eat into labor time that could instead be spent on shipping, receiving, or analyzing goods.

Stale data creates blind spots

Spreadsheets capture snapshots of data, not real-time status. By the time stock levels are manually updated, the warehouse counts have usually moved on – an order may have shipped or a delivery arrived, making the Excel view obsolete. Industry surveys underline the gap: 77% of supply chain leaders say visibility is a must-have, yet only 25% have it. With spreadsheets, teams operate in the dark each shift, unable to see true inventory positions. Planning and fulfilling orders become guesswork rather than precise operations. In other words, leaders lose the agility to adapt to surges or shortfalls. Visibility remains stuck in the past, forcing reactionary decisions and imbalances.

Disconnected systems obscure the full picture

Excel files don’t integrate with scanners, WMS, or ERP tools. Each system’s data must be updated separately, and no one dashboard shows everything together. Managers can end up reviewing reports that have hours-old data, unaware of recent changes. Because these systems are disconnected, teams often must repeatedly ask “how much stock do we really have?” in multiple places. This fragmentation breaks end-to-end visibility and makes coordinated decisions impossible with Excel alone.

Spreadsheets weren’t built for operational agility or integrated decision-making

Relying on spreadsheets forces teams into manual, siloed workarounds that slow everything down. Instead of supporting quick decisions, every new process or product requires custom spreadsheet updates and reconciliation. Here are some inherent limitations of using spreadsheets for modern warehouse operations:

- Single-user editing: Excel requires exclusive access for accurate updates, so teams often pass around separate files instead of collaborating in real time.

- Version mismatches: Without a centralized system, every update spawns a new copy, leading to conflicting records and wasted hours resolving which file is correct.

- Manual data errors: Spreadsheets have no built-in validation, so typos, formula mistakes, and copy-paste errors are common. Research found that about 88% of spreadsheets used for planning contain errors, undermining trust in the data.

- No real-time integration: Excel doesn’t connect to scanners or order systems, forcing staff to manually import and export CSVs. Updates lag, and fresh data stays hidden from decision makers.

- Maintenance overhead: Power users spend excessive time writing formulas and adjusting sheets for new scenarios rather than analyzing data or improving processes.

- Scalability limits: Excel slows down or even crashes with very large inventories or transaction volumes. That forces teams to split data across multiple files or accept incomplete analysis as they grow.

- No audit trail: It’s difficult to track changes or roll back mistakes in spreadsheets, raising governance and compliance risks in fast-moving warehouse environments.

These limitations keep warehouse teams tied to low-confidence data and time-consuming admin tasks. Instead of agility, spreadsheet dependence means labor is spent on firefighting data issues. The result is slower decisions and fractured insight. The next section explains why mid-market warehouses should focus on smarter data integration instead of another costly rip-and-replace bet.

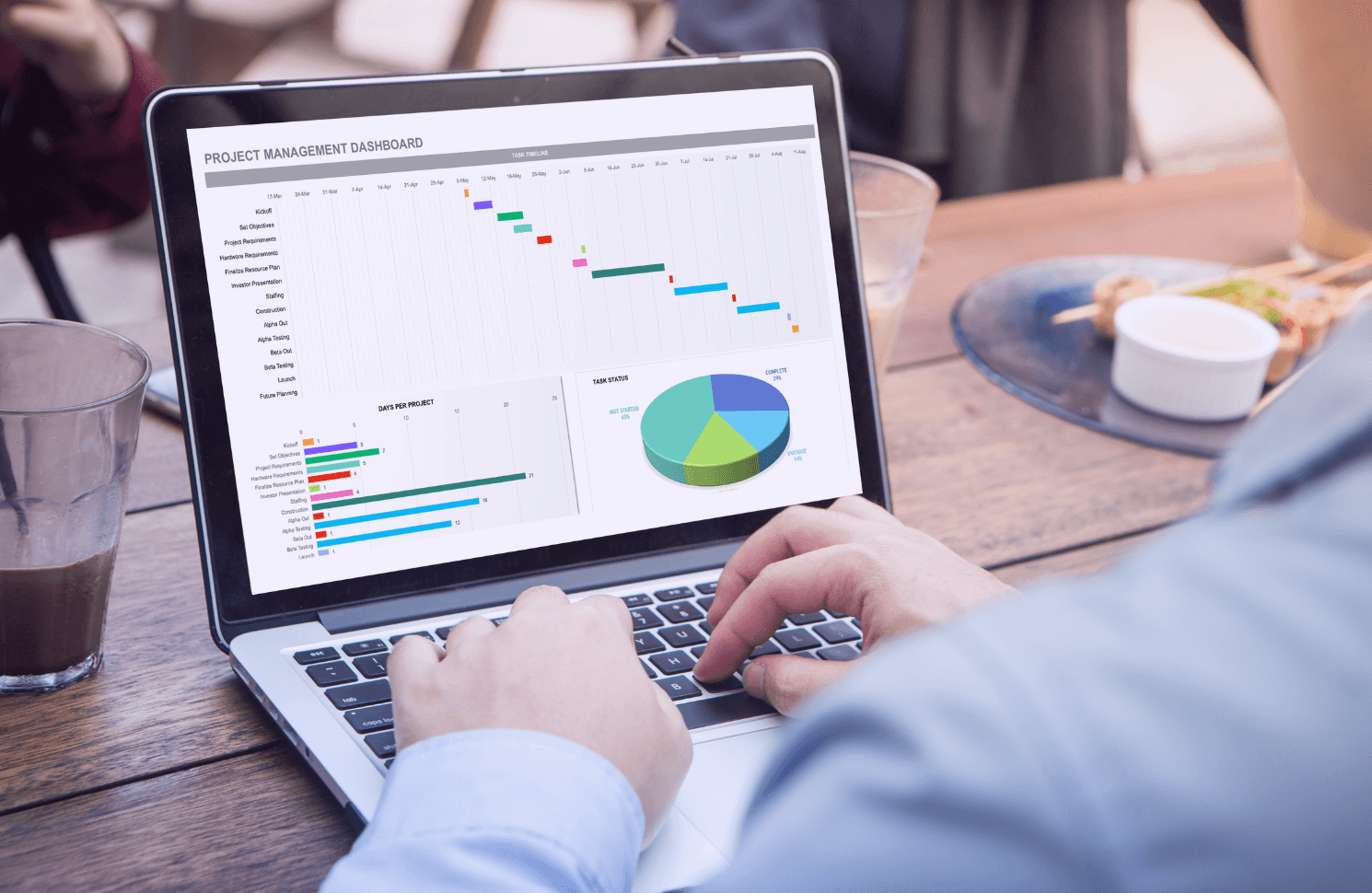

Mid-market warehouses need smarter data, not bigger technology bets

Many mid-market warehouses simply can’t justify a complete overhaul of their systems. Replacing a WMS or ERP can take years and millions, derailing immediate goals. Instead, these companies should focus on smarter data strategies. The fastest wins come from connecting existing tools and injecting real-time data flows. Overlaying a cloud-native integration layer on top of the current WMS, inventory, and fulfillment systems lets companies avoid disruptive change. This approach accelerates ROI: one study found that adding demand-planning software to Excel-based processes boosted forecast accuracy by about 27%, leading to fewer stockouts and lower carrying costs.

"With a smarter data fabric in place, warehouse teams gain real-time visibility without switchover risk."

With a smarter data fabric in place, warehouse teams gain real-time visibility without switchover risk. Inventory leaders can drill into live dashboards instead of chasing Excel updates. IT teams shift from creating brittle reports to optimizing integration pipelines. Orders and shipments flow according to current conditions, not yesterday’s numbers. As a result, decision-making shifts from reactive guesswork to proactive planning, ensuring the business can adapt quickly to demand or disruption. Data-driven agility like this often shows up in improved order accuracy and fewer emergency shipments.

Lumenalta connects your trusted warehouse tools for real-time insight

Lumenalta’s platform connects the existing tools your team already trusts, unifying data into a single, real-time warehouse intelligence layer. This cloud-native integration fabric links WMS, inventory, order, and fulfillment systems, so information flows automatically without ripping out your current software. Warehouse managers instantly see accurate stock and order statuses in one dashboard, while executives gain a holistic view of operations. Real-time metrics update continuously, allowing everyone to act on the same accurate data without delays.

For IT teams, this means ditching spreadsheets and custom scripts in favor of a scalable integration layer. For operations, it means inventory, orders, and returns update live so staff can respond instantly. Early adopters report measurable gains: faster order cycle times, fewer stock discrepancies, and far less manual work. Ultimately, this approach lets warehouses improve speed and accuracy without disruption. The connected data fabric becomes a true business enabler, delivering confident decisions and on-time fulfillment.

Table of contents

- Why Excel is holding modern warehouses back from real-time fulfillment

- Spreadsheets weren’t built for operational agility or integrated decision-making

- Mid-market warehouses need smarter data, not bigger technology bets

- Lumenalta connects your trusted warehouse tools for real-time insight

- Common questions

Common questions

Why is Excel still used in modern warehouse operations if it causes so many delays?

How can I reduce manual reporting work in my warehouse?

Is replacing my WMS the only way to modernize warehouse reporting?

How does poor data visibility impact fulfillment performance?

What kind of ROI can I expect from replacing spreadsheets with integrated warehouse data?

Connect your warehouse tools for real-time insight and faster fulfillment. Say goodbye to manual data wrangling and move forward with confidence.