A CIO’s guide to using AI and computer vision in logistics

JUL. 2, 2025

4 Min Read

You can almost feel the tension in the loading dock when a shipment slips out of sequence.

Missed slots ripple across your network, partners start phoning, and costs climb by the minute. You want the entire chain to self‑correct before phone alarms buzz, not hours later when penalties land. Artificial intelligence paired with computer vision now gives that control. CIOs are leading the charge to deploy it.

Freight volatility, workforce shortages, and tight capital budgets create a brutally simple equation: move more with less risk. Vision‑powered AI pushes real‑time truth into planning engines, so trucks roll full, products stay visible, and invoices match actual service. Early adopters are already shaving days off dwell times and double‑digit percentages off total logistics spend. You need the playbook that turns those results into a repeatable program at the enterprise scale.

"Freight volatility, workforce shortages, and tight capital budgets create a brutally simple equation: move more with less risk."

Key takeaways

- 1. Computer vision in transportation replaces manual checks with automated, real-time validation across warehouses, yards, and freight.

- 2. AI in logistics and transportation enables smarter route decisions, dock orchestration, and inventory prioritization without needing more infrastructure.

- 3. Generative AI supports accurate forecasting by creating thousands of synthetic scenarios and modeling outcomes in seconds.

- 4. Deployment success depends on data readiness, cross-team alignment, and clear governance of AI and vision systems.

- 5. Measurable ROI from AI in transportation logistics comes from faster service, lower costs, stronger compliance, and better planning accuracy.

Why CIOs are prioritizing AI in transportation and logistics

Data silos once limited visibility to yesterday’s numbers, delaying every corrective action. AI in transportation and logistics now blends live camera feeds, telematics, and third‑party signals, producing instant context for each route and warehouse bay. That context feeds optimization algorithms that suggest new load mixes, staffing reallocations, or carrier swaps while there is still time to act. A single orchestration layer surfaces high‑value decisions for operations, finance, and customer service without endless reconciliation.

Board members also watch emissions metrics, insurance claims, and consumer loyalty indices. Computer vision in transportation captures granular proof of condition and chain of custody, reducing disputes and protecting brand promise. Chief information officers track the same feed to confirm governance and cyber posture. Capital markets reward firms that show disciplined adoption and measurable returns, so the technology budget lines up neatly with strategic objectives.

See vision AI in action

Key business use cases for computer vision in logistics

Computer vision in logistics gives digital sight to every node, replacing sporadic manual checks with constant verification. Decision support improves when each pallet, truck, and package carries its own digital signature. These use cases share a common structure: low‑cost cameras feed models trained on years of historical images, which then surface anomalies instantly. Proof points span damage detection to automated invoicing, cutting labor, paperwork, and settlement cycles.

Automated damage detection

Faulty packaging or forklift mishandling often sits unseen until customers complain. Two‑camera rigs on the dock flag dents, tears, or leaning skids as soon as freight leaves a trailer. The system assigns severity scores and triggers photo‑verified claims before the truck even pulls away. Operations teams redirect suspect pallets for rework rather than risking downstream returns.

Insurance carriers favor documented evidence at the first touchpoint. Computer vision for logistics supplies timestamps and SKU numbers, shortening claim adjudication. Finance then links reimbursements to specific invoices, closing the loop. The net effect is fewer write‑offs and stronger service credits.

Shipment tracking and traceability

Bluetooth tags give position, but they miss condition. Vision sensors at choke points confirm seal integrity, label accuracy, and temperature strip color. Anomalies route to traffic control centers that adjust ETAs for any compromised load. Customers receive proactive alerts, avoiding costly rejections at the dock.

Regulators ask for complete audit trails. Computer vision in supply chain operations captures image‑based breadcrumbs every time cargo changes custody. Those artifacts satisfy trade compliance teams during inspections. CIOs appreciate not combing through siloed systems during audits.

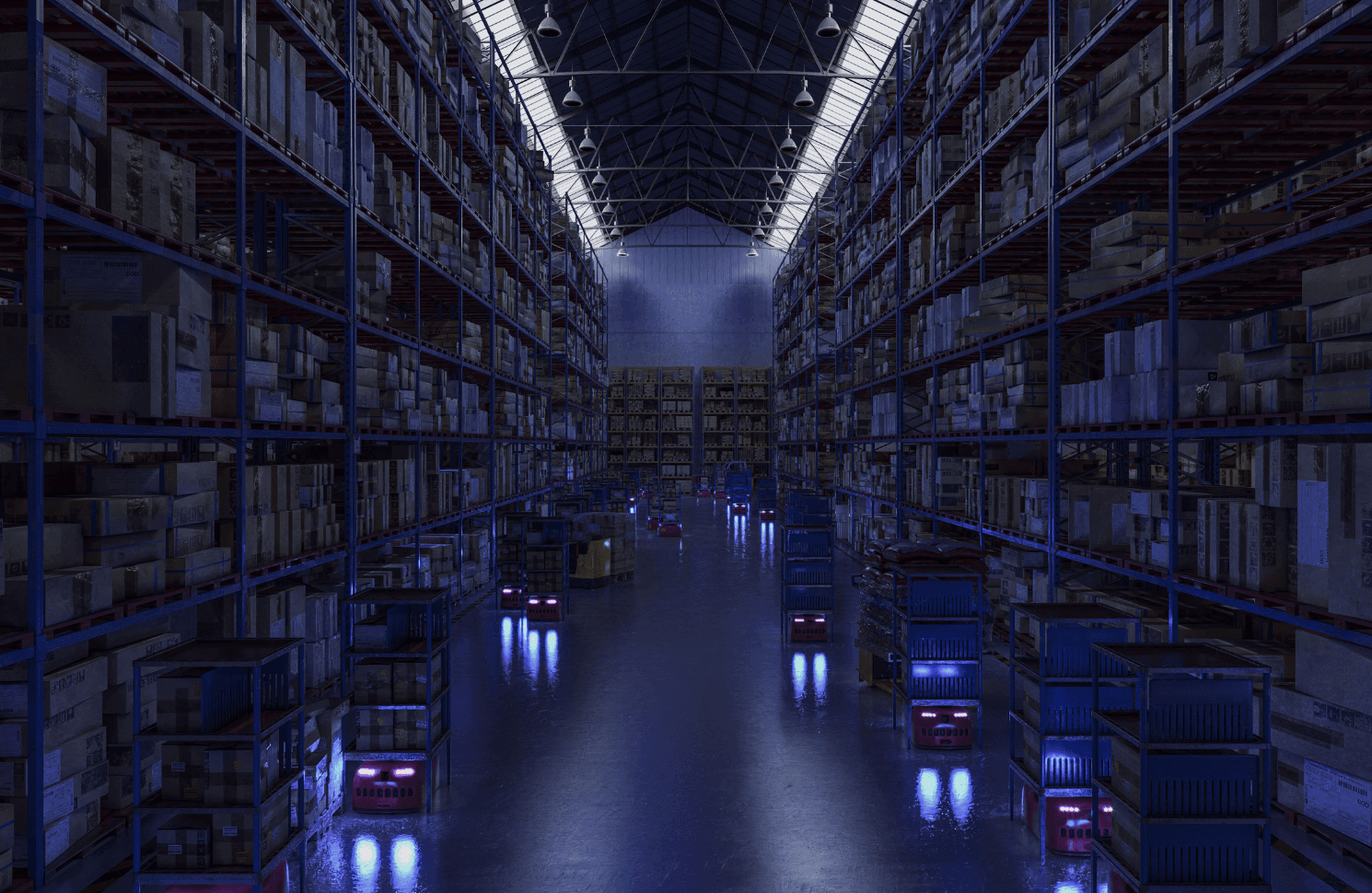

Warehouse put‑away and picking

Bar‑code scans still rely on human steady hands. Ceiling‑mounted cameras map rack positions, guiding workers with augmented pick paths projected on handhelds. Mis‑slotting signals fire instantly, preventing phantom shrinkage and cycle‑count churn. Labor productivity climbs without expanding headcount.

The same network keeps learning from each pass. AI in logistics and transportation recalibrates slotting rules based on velocity, weight, and contiguous picks. That decreases travel distance per shift and trims over time. Performance metrics feed workforce incentive programs that reward accuracy, not just speed.

Yard management

Unattended trailers consume scarce yard space. Vision gates capture license plates and trailer numbers automatically, linking them to transport orders. Dwell timers start the second wheels cross the threshold, not hours later when a clerk updates the manifest. Dispatch gains a live heat map that highlights congestion before it halts throughput.

Site safety also improves. Cameras flag pedestrians in truck lanes and alert guards through wearable haptics. Insurance premiums reflect the lowered incident statistics. CFOs see direct budgeting relief without extra staff.

Regulatory compliance auditing

Cross‑border freight faces strict labeling and hazmat documentation rules. Vision models read multiple languages and hazmat placards, verifying compliance within seconds. Non‑conforming loads reroute to remediation areas before customs officials intervene. Border delays shrink, protecting on‑time delivery metrics.

Records are immutable. Every image stores cryptographic hashes and geotags, creating an evidence stack against potential fines. Compliance officers retrieve proof via self‑service dashboards, freeing IT from custom report requests. The organization stays audit‑ready without overtime.

Computer vision in transportation unlocks many use cases beyond these core scenarios, yet each demonstrated benefit follows the same pattern of instant verification feeding operational choices. Clear ROI presents itself early, inviting wider rollout and cross‑functional alignment. End‑to‑end visibility shifts from aspiration to baseline performance requirement. CIOs then look ahead to bigger optimization layers confident in a solid data foundation.

Benefits of computer vision for supply chain performance

Computer vision for supply chain operations turns visual data into tangible gains. Businesses capture more value when each movement is verified, measurable, and traceable. Investments mature quickly because commodity hardware now pairs with cloud inference, dropping entry costs. Managers gain a clear line of sight from the sensor to savings.

- Quality assurance consistency: Automated inspection reduces subjective judgments and catches subtle defects that slip past tired eyes, lowering return rates and boosting customer satisfaction.

- Dwell time reduction: Instant gate reads and dock status feeds cut idle hours, releasing capacity without infrastructure expansion.

- Labor efficiency: Vision‑guided workflows streamline put‑away, picking, and packing, letting existing teams ship higher volumes every shift.

- Shrinkage avoidance: High‑resolution cameras deter theft and misplacement while giving proof for insurance or legal recourse, protecting margins.

- Compliance assurance: Image logs satisfy safety and customs requirements, preventing penalties and border delays.

- Sustainability tracking: Verified load consolidation and reduced empty miles support emissions reporting, helping firms meet carbon commitments without heavy manual logging.

Computer vision in supply chain operations supplies verified truth at the moment where it matters, shrinking data latency to seconds rather than days. Each listed advantage compounds across thousands of transactions, delivering step‑wise gains instead of isolated wins. Automation also lifts morale by assigning tedious checks to machines and letting people focus on exception resolution. Technology budgets shift from pilot mode to enterprise rollout once decision-makers see the stacked returns.

How AI in transport and logistics supports real-time optimization

Logistics leaders crave up‑to‑the‑minute guidance that keeps fleets, docks, and yards in sync. AI in transport and logistics converts streams of sensor data into optimization suggestions that dispatchers accept or tweak. Continuous recalibration guards against weather disruptions, driver delays, or sudden surge orders. With predictive insight baked into daily routines, decisions shift from reactive firefighting to proactive balance.

"AI in transportation logistics thrives on quality inputs, and computer vision is now the most reliable source of granular events."

Dynamic route re‑sequencing

Traffic feeds, service time estimates, and fuel prices change minute by minute. Optimization engines recalculate drop orders on the fly, then push updates to driver tablets. The driver still controls safety choices, but gains recommended lane changes and window adjustments. On‑time performance advances without extra mileage.

Dispatch supervisors gain visual dashboards that show cost‑to‑serve per stop. That transparency fosters collaborative conversations with sales about customer service levels and minimum drop volumes. The company reinforces profitable behavior while honoring key contracts. Bottom‑line savings arrive within weeks, preserving working capital.

Dock appointment orchestration

Electronic logging devices broadcast inbound ETAs, allowing docks to reshuffle doors before trucks sit idle. Computer vision in transportation logistics confirms actual trailer arrival and departure, eliminating manual check‑in forms. Forklift operators receive tablet prompts that align with updated door schedules. Turnaround time shrinks, freeing capacity for extra loads.

Carriers appreciate shorter wait times, which improves retention and reduces accessorial charges. Shared data builds trust that later supports strategic volume commitments. Finance models those improvements when renewing contracts. Predictable dwell metrics translate into predictable cost forecasts.

Inventory‑aware mode shifts

Inventory control systems feed stock‑out risk scores to transport planners. When high‑priority SKUs fall below safety stock, AI recommends mode upgrades or lane swaps that accelerate replenishment. Cost deltas appear alongside risk savings so managers pick the optimal trade‑off. Service levels hold without chronic airfreight spend.

Sourcing can then shift from buffer stock to just‑in‑time replenishment. Freed‑up capital supports growth projects instead of sitting in warehouses. Planning confidence also increases because data consistency is monitored at each step. The supply chain becomes both lean and resilient.

Energy‑optimized fleet dispatch

Electric vehicles and alternative fuels add new constraints like charge windows and station availability. Optimization models layer state of charge with proposed stops, ensuring range never jeopardizes service. Route planners visualize emission savings and electricity costs side by side with delivery KPIs. This dual lens meets sustainability goals while protecting margins.

Regulators supply credits for emission reductions backed by verifiable telemetry. Accounting tallies those credits as off‑setting revenue, strengthening internal business cases for future electric fleet orders. Operations staff gain automated custodian schedules based on battery health predictions, extending asset lifespans. Network modeling cycles get shorter because up‑to‑date data feeds algorithms hourly.

AI in transportation logistics thrives on quality inputs, and computer vision is now the most reliable source of granular events. Instant optimization across routes, docks, inventory, and energy unlocks compounding value. Cost, service, and sustainability goals move in the same direction instead of trading off. That unity accelerates adoption among stakeholders who once guarded their own metrics.

See vision AI in action

What CIOs should evaluate before adopting computer vision solutions

Computer vision for logistics brings strategic upside, yet rollout missteps can stall progress. Careful assessment saves rework and secures stakeholder confidence. Aligning technology, process, and governance from day one avoids hidden integration traps. A structured checklist simplifies purchasing decisions.

- Business objective clarity: Outline financial targets, service improvements, and compliance metrics so solutions map cleanly to executive scorecards.

- Data pipeline readiness: Confirm edge bandwidth, cloud ingestion limits, and retention policies to avoid video bottlenecks that cripple inference speed.

- Model governance: Define version control, retraining schedules, and bias checks to keep predictions accurate and audit‑worthy across geographies.

- Cybersecurity posture: Validate encryption for data at rest and in transit, plus strict access controls, safeguarding sensitive shipment imagery.

- Change management strategy: Equip supervisors with playbooks and training so adoption flows through frontline teams instead of stalling at pilot labs.

- Vendor roadmap visibility: Request long‑term support timelines and public APIs so future integrations remain flexible rather than locked.

Well‑defined criteria protect budgets and eliminate scope creep. Procurement teams appreciate measurable checkpoints instead of vaguely defined “innovation” goals. Stakeholder alignment grows when each item links to quantifiable outcomes. The net result is a solid launchpad for broader AI programs.

How generative AI in transportation and logistics can support forecasting

Generative AI in transportation and logistics crafts synthetic scenarios at machine speed, letting planners test responses before disruptions hit. Traditional forecasting uses historical averages, yet volatility renders past performance unreliable. Generative models spin thousands of plausible demand curves or weather sequences, feeding risk ranges into supply and transport plans. Decision confidence rises because simulations show explicit cause‑and‑effect paths.

Scenario planning with synthetic data

Generative networks create realistic but artificial shipments, traffic patterns, and supplier lead times. Planners stress‑test operations against new market entries or geopolitical shifts without exposing confidential client data. Sensitivity analysis uncovers weak links in supplier tiers or mode splits. Executives commit mitigation budgets only where impacts exceed tolerance thresholds.

Regulators sometimes restrict data sharing across borders. Synthetic sets bypass constraints because they never trace back to actual people or goods. Research teams collaborate freely, accelerating method improvements. Intellectual property remains safe within corporate walls.

Weather‑adjusted demand projections

Storms and heat waves tilt consumer demand and impair routes. Generative AI spawns weather perturbations across key corridors, linking them to historical buying patterns. Forecast engines adjust safety stock and driver schedules days in advance. Service reliability holds even during severe disruptions.

Insurance premium models feed on the same synthetic scenarios, quantifying expected claims under harsh conditions. Finance uses those estimates to structure surplus coverage or catastrophe bonds. Integrated planning shrinks the gap between physical risk and financial resilience. Data remains fresh because models retrain after each season.

Dynamic pricing guidance

Spot rates react to capacity swings that legacy systems often miss until invoices arrive. Generative algorithms sketch likely capacity curves and blend them with cost‑to‑serve thresholds. Sales receive guidance on minimum viable rates that still protect the margin. Negotiations become fact‑based rather than anecdotal.

The same guidance helps procurement secure fuel contracts or rail slots at optimal times. Cost exposure narrows because hedges align with statistical corridors. Treasury can then forecast cash flows more predictably. Investor relations welcomes that transparency.

Asset lifecycle prediction

Generative AI fabricates wear‑and‑tear sequences under many duty cycles. Maintenance planners examine the output to optimize part replacements before failures occur. Assets retire on a schedule that balances depreciation and uptime. Capital budgeting benefits from smoother expenditure curves.

Manufacturer partners access aggregated degradation patterns to enhance future designs. Warranty claims drop because usage profiles align with engineering tolerances. Environmental impact lessens because equipment runs at peak efficiency longer. Stakeholders see sustained value extraction over the asset life.

Generative AI acts like a flight simulator for logistics decisions. Synthetic futures expose risk hot spots, fine‑tune spending, and preserve customer commitments despite volatility. Financial teams gain stronger forecasting accuracy and fewer surprises. CIOs thus anchor technology programs around measurable planning improvements instead of abstract hype.

Common challenges with AI in transportation logistics and how to address them

Even proven solutions stumble without guardrails. Proactive risk mitigation keeps projects on schedule and value on track. Knowing the usual pitfalls lets teams plan countermeasures early. Stakeholders then trust the rollout.

- Data quality gaps: Missing labels or corrupted frames hinder model accuracy; enforce strict camera calibration routines and automated data validation.

- Over‑customization: Too many one‑off tweaks stall updates; adopt modular architectures that reuse core components across locations.

- Talent scarcity: Vision specialists are scarce; cross‑train existing analysts on curated courses and secure fractional expert support for complex tasks.

- Surprise integration costs: Legacy WMS or TMS systems may lack APIs; budget adapters and middleware during initial financial planning.

- Change fatigue: Frontline teams juggle multiple initiatives and sequence rollouts with clear value demonstrations and phased feature releases.

- Security blind spots: Video streams attract attackers; isolate inference nodes within zero‑trust networks and maintain strict patch cadence.

Clarity on these obstacles calms executive nerves. Project managers validate controls with simple scorecards, paying attention to impact instead of crisis response. Well‑paced rollout plans stretch wins across quarters, reinforcing momentum. Enterprises then grow from pilot success to enterprise coverage with fewer headaches.

See vision AI in action

How Lumenalta helps CIOs deliver value with AI in logistics

Lumenalta guides technology leaders through every phase, from first‑mile feasibility to enterprise‑wide optimization. Our architects map camera deployments to your exact process bottlenecks, then align digital twins and optimization layers with the metrics that already appear on board packets. Implementation teams integrate computer vision, edge processing, and cloud orchestration in parallel sprints, shaving months off time‑to‑value while containing risk. We provide pre‑built adapters for leading WMS and TMS platforms, so imagery, sensor readings, and financial records converge in a single data fabric. Continuous model monitoring, bias checks, and cybersecurity updates arrive as managed services, freeing your team for high‑value strategy work.

CIOs also rely on us for strategic roadmaps that secure executive buy‑in. Financial analysts within our team translate technical milestones into NPV, payback, and carbon‑reduction metrics that matter to boards and investors. Workshops with operations, finance, and compliance leaders create shared success criteria and phased funding approvals. Our co‑creation rhythm produces weekly deliverables, giving stakeholders tangible progress instead of long‑cycle promise decks. Trust builds when cross‑functional teams witness measurable gains—shorter dock turns, confirmed compliance, and lower total logistics cost per unit.

Table of contents

- Why CIOs are prioritizing AI in transportation and logistics

- Key business use cases for computer vision in logistics

- Benefits of computer vision for supply chain performance

- How AI in transport and logistics supports real-time optimization

- What CIOs should evaluate before adopting computer vision solutions

- How generative AI in transportation and logistics can support forecasting

- Common challenges with AI in transportation logistics and how to address them

- How Lumenalta helps CIOs deliver value with AI in logistics

- Common questions

Common questions

How can I use AI in transportation and logistics to improve delivery accuracy?

What is the best way to start implementing computer vision for logistics?

How does generative AI help with logistics forecasting?

What should I watch out for when deploying AI in transportation logistics?

How do I measure ROI from AI and computer vision in logistics?

Don’t wait for alarms to tell you what already went wrong. Use vision-powered AI to predict, prevent, and outperform.